-

Anfibio Revo CL

-

Anfibio Revo XL+

-

Anfibio Omega C2(+)

-

Anfibio Omega C2B+

-

Anfibio Rebel 3KL+

-

Anfibio Rebel Duo (+)

-

Anfibio Sigma TXLB+

-

Anfibio Sigma TXL (+)

-

Anfibio Sigma TX

-

Anfibio Rebel 2K

-

Anfibio Delta MX

-

Anfibio Alpha XC

-

Anfibio Nano RTC (XL)

-

Anfibio Nano SL

-

Anfibio Revo CL

-

Anfibio Revo XL+

-

Anfibio Omega C2(+)

-

Anfibio Omega C2B+

-

Anfibio Rebel 3KL+

-

Anfibio Rebel Duo (+)

-

Anfibio Sigma TXLB+

-

Anfibio Sigma TXL (+)

-

Anfibio Sigma TX

-

Anfibio Rebel 2K

-

Anfibio Delta MX

-

Anfibio Alpha XC

-

Anfibio Nano RTC (XL)

-

Anfibio Nano SL

- Packrafts

- Paddle

- Packing

- Clothing

- Accessories

Back

Back

Back

Design &

Technology

This is how new Anfibio products are created for your next adventure. On this page we explain the materials, construction and concepts, from TubeBags to VenturiTube to TwinTailTM. Welcome to the Making of Anfibio Packrafting Gear.

Insights into our designs and technologies.

All features graphically illustrated and comprehensively described.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPrinciples

& Concepts

The base of our developments and source of ideas is listening, observing, applying and thinking outside the box. Materials, construction and concepts always follow the principle of function (performance) – weight (packing size) – sustainability (durability).

A product’s functions are our top priority. The equipment should be used flexibly and ideally fulfil several purposes during the trip. A multibag for example is used as a drybag in the morning, as a seat during the day and to shower in the evening. We develop concepts for packrafting adventures.

Weight and packing size are minimised as far as possible. The principle is: as much as necessary; as little as possible. To find a good balance we rely on our experience and a solid database.

We aim for long life cycles and take our sustainability criteria into account during development. This includes maintenance and repair options. Resource-optimised manufacturing often also saves weight and cost.

Listening

Discussions with partners and future users provide us with valuable feedback, wishes and visions. They are an important basis for new ideas and improvements.

Analysing

We carefully observe and analyse our products and materials in use, both ourselves and with customers. In videos, under real conditions and all with a sense of proportion.

Self testing

The best products are also made for oneself. Scratch your own itch! Trying things out and doing our own tests are the most important steps in product development.

Thinking outside the box

We are not afraid to break our own conventions. New approaches provide new solutions.

Development has no beginning and no end, it is a cycle.

Design

Thoughts are collected, discussed, declined, agreed and redrawn - until the first prototype is created.

Elaboration

A lot of water flows down the stream until an idea becomes a finished product. Unlike us, paper is known to be patient.

Elaboration

A lot of water flows down the stream until an idea becomes a finished product. Unlike us, paper is known to be patient.

Material

The world of materials is colourful. We select them depending on requirements or have them created according to our own parameters.

Material

The world of materials is colourful. We select them depending on requirements or have them created according to our own parameters.

Manufacturing

With longterm, global production partners, we have access to a broad portfolio of specialist technologies and are not tied to individual manufacturing expertise.

Manufacturing

With longterm, global production partners, we have access to a broad portfolio of specialist technologies and are not tied to individual manufacturing expertise.

Workmanship

Serial production takes place in small, handmade batches (manufactory processing) in China, Germany and France. This craftsmanship and the close cooperation with our manufacturers enable us to guarantee consistently high quality.

Workmanship

Serial production takes place in small, handmade batches (manufactory processing) in China, Germany and France. This craftsmanship and the close cooperation with our manufacturers enable us to guarantee consistently high quality.

Service

Once the current prototypes have met all requirements and are ready to move from serial production to logistics, service begins. If individual adjustments or repairs are needed, our experts can carry them out.

Service

Once the current prototypes have met all requirements and are ready to move from serial production to logistics, service begins. If individual adjustments or repairs are needed, our experts can carry them out.

Inspiration

Ideas and improvements arise before and during design, while testing and in regular use. Sometimes we test products ourselves, sometimes we get valuable feedback from our customers and partners.

Inspiration

Ideas and improvements arise before and during design, while testing and in regular use. Sometimes we test products ourselves, sometimes we get valuable feedback from our customers and partners.

The materials are selected for the best balance of weight and durability.

Anfibio Packrafting Gear

Our

Materials

State-of-the-art lightweight materials such as fibreglass, carbon, TPU and nylon are used in all components of Anfibio products. Most of them are made of composite structures (fibre and matrix), such as coated nylon (boats, clothing, bags), laminated fibreglass (paddles) or injection-moulded (fibre-reinforced) plastic (accessories).

in every detail

The essential

component

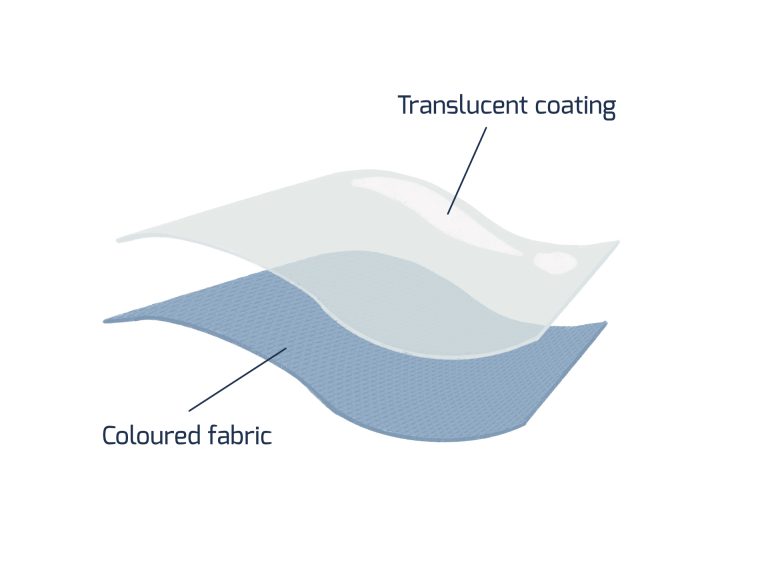

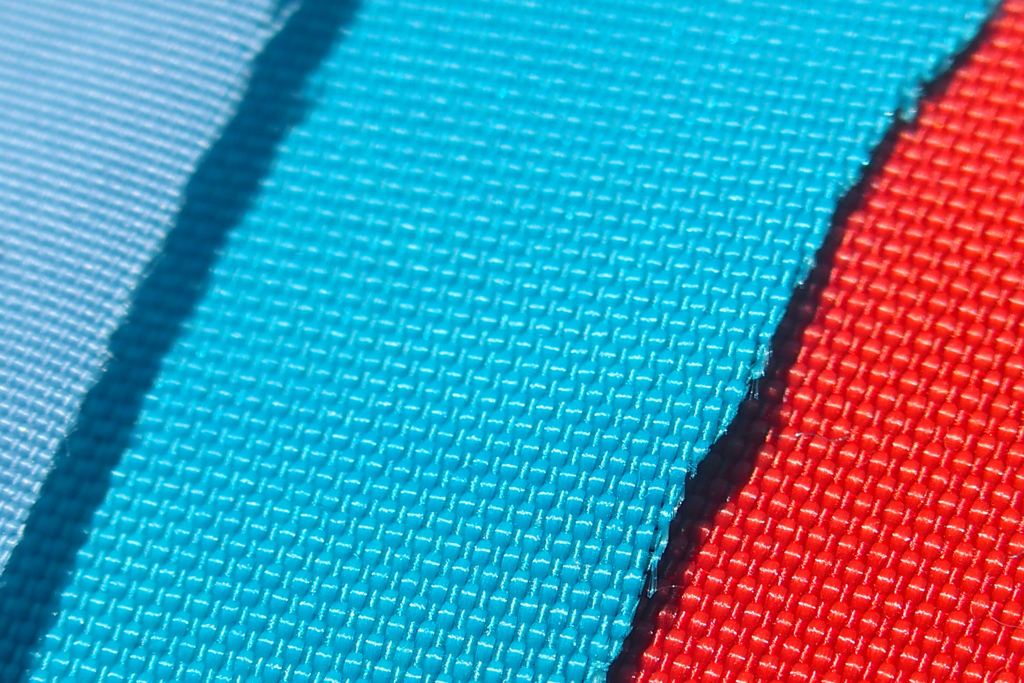

For our boats and many accessories, we exclusively use TPU (thermoplastic polyurethane) coated nylon fabric with different fibre strengths and coating thicknesses, depending on the requirements and area of use. This material class provides excellent basic properties for packraft construction.

A special feature of our tube materials is the use of a translucent TPU coating. The saving of colour pigments in the coating saves weight and cost. The colouring comes exclusively from the coloured nylon base fabric, which is colored anyway.

Advantages of TPU nylon

While the fibres absorb tensile and shear forces, the TPU coating provides resistance to abrasion and makes the material airthight and waterproof. The fibre composite thus has high strength combined with low weight.

Unlike PVC, TPU coating does not require any chemical softeners. This is not only better for the environment, but also ensures greater resistance to ageing (no volatile elements leading to hardening of the fabric).

Unlike many other materials, (aliphatic) TPU coatings do not show any signs of wear and tear even after many hours under the sun’s intense UV. This means longer tours through southern regions are possible without problems with the material.

Using high temperature- or radio frequency welding, TPU will deform and reliably fuse to itself (unlike rubber, for example) making an extremely strong bond. Since no additional elements like glue are needed, this also saves additional weight. For the sake of the environment, we completely dispense with adhesives in the production process.

TPU coated nylon can also be used in very low temperatures, as the material neither stiffens nor becomes brittle, unlike PVC. It retains full flexibility even in sub-zero conditions.

The smooth and shiny surface of the transparent tube coating is especially

scratch resistant.

Our special textile fabric with different yarn thicknesses and weave densities achieves

high tear resistance.

The interaction of these properties results in a unique ratio of weight to durability, which is demonstrated in continuous measurement and test procedures to verify adhesion and tear resistance.

Material version

Plus(+)

We use two type of TPU nylon. A quality that has been tried and tested for many years is used as standard. Our basic variant is made of lightweight 210 denier nylon as well as 420 denier nylon with a 0.1 mm thick TPU lamination (on one or both sides).

For special applications and selected models, there is the Plus(+) variant of our TPU nylon, which is only 17% heavier but 80% stronger. With a higher weave density, stronger fibres and increased layer thicknesses, it is the most durable material currently available for its weight.

The Plus(+) materials can be recognised by their own colours Pacific Blue+ and Terra Red+. But they are also available in the familiar Fresh Green+.

Great material! Here I can touch everything and move freely.

Arco, best friend of photographer Lisa-Kristin Schrötter

Construction &

processing

Our boats and many accessories are inflatable products, so there are always physical limits to the design. However, we use the given scope constructively as much as we can to tailor the boat’s (and other products) handling characteristics for the intended use.

Ultralight design

Anfibio combines the ultralight concept with robust construction. The glue-free build is only one aspect of our lightweight but sturdy design. Our equipment forgoes unnecessary elements, minimises wherever possible (e.g. the seams) or incorporates design with more than one function (backrest as a support for the spraydeck, for example). Concentrating on the essentials results in the clear design and minimal weight.

High quality processing

Our manufacturing methods such as high-frequency and thermal welding, sewing techniques and cutting are state-of-the-art. All joints are 100% welded instead of glued. This reduces weight and costs while increasing increases durability. The tubes are additionally sewn. We offer an extended 3-year warranty on materials and workmanship for long-lasting paddling pleasure.

Less is more freedom.

Anfibio Packrafting Gear

Matter of

Shape

Symmetry & volume

Profile & rocker

Length & width

Function on board

Konvention über Bord

In addition to smaller, sustaining improvements, we also drive developments forward with completely new solutions. Here are some of our features and innovations:

TubeBags

Anfibio TubeBags consist of tube zips with integrated inner pockets to take luggage. The luggage compartments are separated from the air chamber of the boat. The construction is immune to dirt and wear. A possibly damaged zip will not cause the boat to leak. The pockets also ensure a firm vacuum sealed positioning of the load.

RTC

With the RTC (Roll Top Closure), the entire volume of the tube can be used for luggage transport. The opening (and closing) of the tube is done via an airtight roll top closure. Specifically developed technologies and materials ensure the seal, which cannot be compared with normal dry bags. The construction is robust, simple and reliable.

TubeBag in use

RTC

With the RTC (Roll Top Closure), the entire volume of the tube can be used for luggage transport. The opening (and closing) of the tube is done via an airtight roll top closure. Specifically developed technologies and materials ensure the seal, which cannot be compared with normal dry bags. The construction is robust, simple and reliable.

J-Deck

Designed specifically for Anfibio Packrafts, this spraydeck offers comfort and safety with simplicity. The J-shaped combination of Velcro and zippers is ergonomic, beginner-friendly (simplified exit and entry) and weight-optimised (reduced cuts, few seams, no individual parts or frames). The long chimney ensures freedom of movement and good coverage.

Anfibio Nano RTC

J-Deck

Designed specifically for Anfibio Packrafts, this spraydeck offers comfort and safety with simplicity. The J-shaped combination of Velcro and zippers is ergonomic, beginner-friendly (simplified exit and entry) and weight-optimised (reduced cuts, few seams, no individual parts or frames). The long chimney ensures freedom of movement and good coverage.

Overlaping floor

Where useful and necessary, certain models have a double welded floor which provides additional protection for the side tubes. In this area, two layers of material lie on top of each other. The adhesive-free construction (recognisable by the two parallel welds at the floor) is a special technology. This means maximum reinforcement with minimum use of resources.

Overlaping floor

Where useful and necessary, certain models have a double welded floor which provides additional protection for the side tubes. In this area, two layers of material lie on top of each other. The adhesive-free construction (recognisable by the two parallel welds at the floor) is a special technology. This means maximum reinforcement with minimum use of resources.

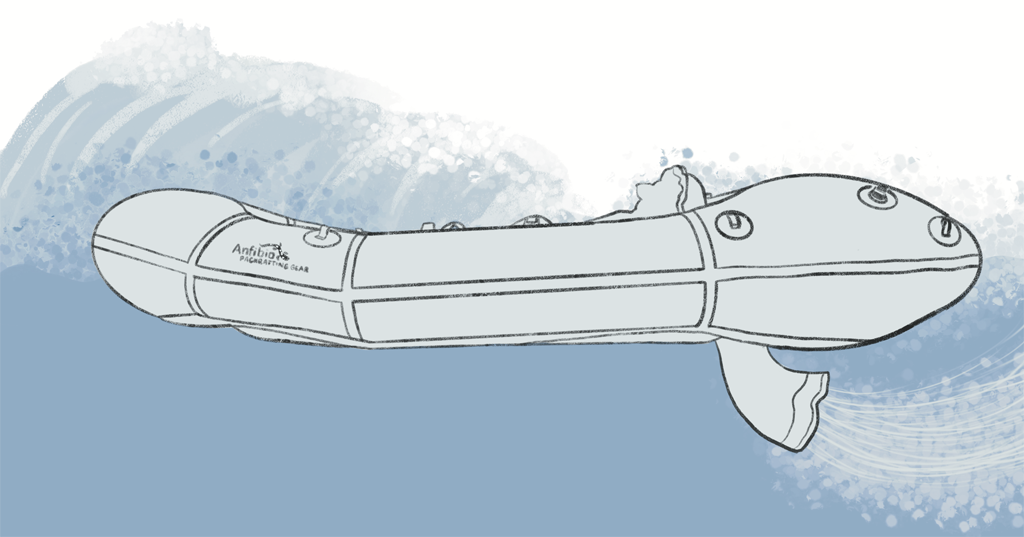

TwinTail

The TwinTail design refers to the eye-catching, V-shaped stern of the boat. Inspired by the design of modern surfboards, this construction offers an aesthetic component as well as functional value. It combines the directional stability of a single keel with the stability and balance of a wide tail, which counts when bracing, edging and accelerating in white water.

TwinTail

The TwinTail design refers to the eye-catching, V-shaped stern of the boat. Inspired by the design of modern surfboards, this construction offers an aesthetic component as well as functional value. It combines the directional stability of a single keel with the stability and balance of a wide tail, which counts when bracing, edging and accelerating in white water.

VenturiTube

The VenturiTube is a floor draining hose. Due its bailing function, the boat does not need a spray deck. Overflowing (white) water, splashes or rain drain off. The VenturiTube can be closed tightly, so you get a classic, closed boat for calm waters.

Registered design

VenturiTube

The VenturiTube is a floor draining hose. Due its bailing function, the boat does not need a spray deck. Overflowing (white) water, splashes or rain drain off. The VenturiTube can be closed tightly, so you get a classic, closed boat for calm waters.

Presented with "MDR Einfach Genial"© 2024 – Anfibio Packrafting

Herzlich willkommen bei Anfibio

Was ist dein Anliegen? Womit können wir dir helfen?

Produkt & Beratung

Der Kundenservice unseres Stores berät Sie gern zu Ihrem Anliegen.

Geschäftskunden & B2B

Sind Sie an zuverlässiger und namhafter Ausrüstung inkl. Beratung für ihr Geschäft interessiert?

Zulieferer & Dienstleister

Wir sind an langfristigen Partnerschaften mit internationalen Lieferanten und Dienstleistern interessiert.

Karriere & Bewerbung

Sie möchten Teil unseres Teams werden und Ihre Begeisterung für die Freiheit am Wasser zum Beruf machen?

You are currently viewing a placeholder content from OpenStreetMap. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information